and why do I need it?

The ‘OTC Report’ (in the September-October Communicator at https://bit.ly/SARC21SepOct) mentions bentonite as an aid to achieve better RF grounding… but what exactly is this stuff?

In geology, the term bentonite is applied to a type of claystone composed mostly of montmorillonite. It forms by devitrification of volcanic ash or tuff, typically in a marine environment. This results in a very soft, porous rock that may contain residual crystals of more resistant minerals, and which feels soapy or greasy to the touch. However, in commerce, the term bentonite is used more generally to refer to any swelling clay composed mostly of smectite clay minerals.

Sodium bentonite expands when wet, absorbing as much as several times its dry mass in water. Because of its excellent colloidal properties, it is often used in drilling mud for oil and gas wells and boreholes for geotechnical and environmental investigations. The property of swelling also makes sodium bentonite useful as a sealant, since it provides a self-sealing, low permeability barrier. It is used to line the base of landfills, for example. bentonite is part of the backfill material used for waste isolation. Various surface modifications to sodium bentonite improve sealing performance in geo-environmental applications, for example, the addition of polymers.

Here in BC, bentonite was installed in slurry walls in North Vancouver, Quesnel and Williams Lake to stop the migration of railway diesel contamination to adjoining properties. It was also used it to seal up abandoned environmental monitoring wells, and is used as pond liner to stop the water from seeping away.

Sodium bentonite can be combined with sulfur as fertilizer prills. These permit slow oxidation of the sulfur to sulfate, an important plant nutrient, and maintain sulfate levels in rainfall-leached soil longer than either pure powdered sulfur or gypsum. Sulfur/bentonite pads with added organic fertilizers have been used for organic farming.

The main uses of bentonite are in drilling mud and as a binder, purifier, absorbent, and carrier for fertilizers or pesticides. As of around 1990, almost half of the US production of bentonite was used as drilling mud. Minor uses include filler, sealant, and catalyst in petroleum refining. Calcium bentonite is sometimes marketed as fuller's earth, whose uses overlap with those of other forms of bentonite.

Bentonite is used in a variety of pet care items such as cat litter to absorb pet waste. It is also used to absorb oils and grease.

What you should know when using ground enhancement material

Under almost all soil conditions, the use of a ground enhancement material will improve grounding effectiveness. Some are permanent and require no maintenance. You can use them in areas of poor conductivity, such as rocky ground, mountaintops and sandy soil, where you can't drive ground rods or where limited space makes adequate grounding difficult with conventional methods.

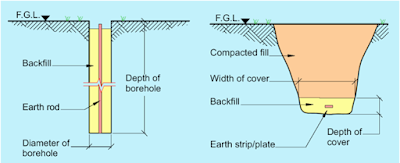

Bentonite is used to lower the resistance to earth by providing ground enhancement effectively reducing the resistance between the soil and earth electrode (such as copper earth rod or earth mats) by retaining moisture. This inherent ability to absorb and retain rainwater increases the electrical conductivity of the earthing compound in positive correlation to local climatic conditions, specifically average rainfall levels. Typically, the compound has a 3 ohms.m resistivity level – Bentonite compound is a cost-efficient material for backfill of earth electrodes and improving performance when it is physically impossible to drive the earth rods deeper and where challenging ground conditions exist such as rock, granite, etc.

Chemical treatment or backfilling of the soil in close proximity to the location of an underground earthing electrode is an established and traditional method of lowering ground resistance for substation earthing on high resistivity ground – such soil backfilling for electrical grounding improvements is commonly used.

There are several kinds of ground enhancement material available. But use care when choosing the material. It should be compatible with the ground rod, conductor, and connection material. Some options include bentonite clay, coke powder, and specially engineered substances.

Conduction in bentonite clay only takes place via the movement of ions. Ionic conduction can only occur in a solution, which means the bentonite clay must be moist to provide the required resistance levels. When bentonite clay loses moisture, its resistivity increases and volume decreases. This shrinkage results in a discontinuity in the contact between the bentonite clay and surrounding soil, which further increases system resistance.

A noncorrosive low-resistance enhancement substance is a conductive cement that you can install wet or dry. Depending on the substance, it will not leach into the soil and meets EPA requirements for landfill. The railroad and utility industries have successfully used this material. When installed dry, it absorbs moisture from surrounding soil and hardens, retaining moisture within its structure. When used dry, no mixing is required, and you achieve maximum efficiency in a matter of days. This is because it absorbs enough water from the surrounding soil. You can also premix it with water to a heavy slurry. You can add this to the trench containing the grounding conductor or use it around a ground rod in an augered hole. The material binds the water into a cement making a permanent, highly conductive mass.

Some products offer a test-proven resistivity of 0.12 ohm-m or lower, compared with 2.5 ohm-m for bentonite clay. Unlike bentonite clay, the cement-like material does not depend on the continuous presence of water; nor does it require periodic charging treatments or replacement.

An ideal ground enhancement material should not require maintenance. When designing or installing a buried grounding system, look for materials that do not dissolve or decompose over time, require periodic charging treatments or replacements, or depend on the continuous presence of water to maintain conductivity.

~ Internet sources including:

https://www.powerandcables.com/product/earth-tapes-rods-bars-copper/bentonite/ and https://youtu.be/hHtIYboE8NE

No comments:

Post a Comment

Sorry, but due to spam, only SARC member accounts may comment.

Note: Only a member of this blog may post a comment.